2 front Sportster cylinders & heads

I’ve been asked whether it’s possible or practical to put these on a 45. Basically, it has the same problems as 2 fronts on a Sportster.

This is a lot more trouble than it looks. The intake ports are between the heads and too close together. The front carburetor must pass by the new rear exhaust port - much too tight. In my opinion, both intake ports have to be moved - cast iron welding is expensive and difficult. Some of these motors were made with 2 rear cylinders just to get better clearance, but it looks terrible. Both carburetors will have leg clearance problems on the left side.

You need welding in a different place in the rear right case because of the irregular Sportster cylinder base flange pattern. I think you can just bolt the extra front head onto the rear barrel, but all the fin interrupts for pushrod clearance will be wrong - major grinding. The new pushrod angles are wrong on the rear cylinder (minor grinding), since the rocker box pushrod tube receptacles and rocker arm sockets are not in the same position, I don’t know anything that can be done about it.

The 2 rear cylinder cams (#1 & 2) have to be re-timed, a simple tooth rotation may bring you close. No, you can’t just put them upside down; they’re off by the LSA (100-105° or so), which is not an even number of teeth (each tooth is 25.71°). At worst, they’ll have to be cut off the gear and re-positioned. The 2 intake valves MUST close at the same time ABDC. Remember the “master” cam (#2) is now an exhaust cam, so when you move it all the timing marks are meaningless.

A Sportster front exhaust pipe won’t be any worse than on a “normal” Magnum (!), but the rear pipe must pass right along the pushrods, ignition, your leg, brake pedal, etc. I don’t know how close an extra front pipe will work here - it’s where I’d start.

It’s probably been done, but I wouldn’t try it myself, too much work. |

Evo Sportster parts

Rather than answer the question directly, look the 45 motor. Then look at the Evo parts. Duh. If this isn’t enough, the Evo top end is much taller than the iron Sportster (even with it’s much shorter rod), so more cutting, welding, moving etc. in the chassis - even a Sportster chassis - will be required. The shorter Sportster Evo rod (6.926” vs. 7.4375”) could potentially be used on the S&S 45 replacement flywheels (but not in the 45 or WR flywheels - too wide) to shorten the motor height a bit. This might be possible if the bore size is kept to | |

|

3.1875” or less (= 1000cc; 883 at 3.000” even better), but would require some major precision work to the barrels, total butchery of the frame, etc.

The stud locations on the Evo are far outboard of any metal on the 45 case, so the only way I can see is to reduce the OD of the aluminum barrel and iron liner to 3.1875”-3.375” in a band about 1” high, beginning 1” up from the base, and make a flange out of the aluminum below it to use new studs that, (although relocated) would be possible to place on the 45 deck. The existing spigot would have to be lathed down to 3.1875”- 3.375” OD at the deck surface.

Unless you use a stroker piston or plate, the Evo cylinder is .680” too short (5.330” vs. 4.650”). The taller 1340cc big twin cylinder look like the cure, but won’t work since the bore size is already larger than the intended spigot OD - there won’t be any metal to make the new flange.

The heads must be from an 883cc or you won’t have any compression (the chamber volume is too big). The Evo is a quench motor just like the 45, so piston to head clearance is critical - you can’t just get the compression height close, it has to be precise.

This is all going to take rocket science and $$$$$$. The Evo parts that are cheaper are the barrels and heads; the rocker boxes, shafts, covers, etc. are more expensive than iron Sportster.

If the rod is long enough (not that this will be easy), the cylinder spigot can be eliminated completely and the bore size can exceed the case opening ID. Just needs a substantial “transition plate” with some recessed (countersunk allen-head?) stud pattern that fits the deck surface, adequate thickness to prevent failure, and a second stud pattern in the plate suitable for the big cylinder. As long as the skirt ends above the plate’s upper surface the bore size can be anything you want. If the cylinder of choice has a spigot in the stroke + CD + skirt length (finned area not long enough to contain the work path) the plate can be longer to accomodate (all or part of) it. |

British OHV parts

For a more complex but interesting project, the cylinder, head, rocker assembly etc. from some of the small to mid-sized Brit singles (BSA, Triumph, Matchless, AJS, Norton, Ariel, Royal Enfield, etc.) can be adapted. I suggest looking first at 250 & 350cc (not 500) unit and pre-unit motors. Since fewer dimensions will match, more planning is needed, spares are harder to find, etc. It may also be possible for the motor to be shorter (clear the frame) if the stroke is reduced (S&S can do this but $$ and not much change). Easier to use S&S wheels and alternate rod lengths, since XL type rods are available in lengths of 6.926”, 7.113”, 7.27” and 7.47” long. This will be $$$.

Another possible is Ariel or Royal Enfield twin parts since they use symmetrical separate barrels and heads. You would have a choice of single carb (original left cylinder = 45 rear cylinder, right = front) or 2 carbs (2 rights or 2 lefts).

In most cases at least one port (and up to all 4) has to be moved laterally and/or up, but not too bad since these are frequently alloy and therefore weldable. |

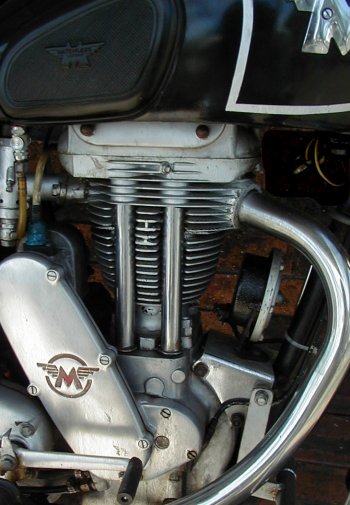

The placement of the British tappets in the right case will affect how far off the geometry is on the 45, since (unless they're identical, which won't happen) there will be a “departure angle” between the intake and exhaust pushrods, and between any pushrod and the bore axis (22½° from vertical). The A.M.C. (Norton, Matchless, A.J.S.) singles have been done before, here’s an example, left. Click for a larger view. |

|

|

Shown right is the Matchless 350 source engine, note that the exhaust pushrod tube is forward of the bore center, the intake pushrod tube is more centered. This will align fairly well with the 45’s front tappet blocks (which have a similar relative position), but badly with the rear tappet blocks. Click for a larger view.

The BSA “B” and “M” series pre-unit singles (not the B40, B50, Victor unit engines) may be easier, since they also have 2 cams but the tappets are closer to being evenly split on the bore axis. There will still be an error, but at least it won’t go on the right direction on the front cylinder and the wrong direction on the rear cylinder. |

Older “D” (1929-31) and “R” (1932-36) engines

This would make me very nervous not only because of the age of the cases, but the pinion oiling method may not be sufficient to the extra load - power is tripled - and the total oil volume available may not be enough to supply both the crankpin and rocker valve gear.

A Mikuni etc. vacuum-operated fuel pump may be suitable as a return oil pump using crankcase pressure as a power source, drawing oil from the purge valve and discharging back to the tank with a T in the return line to supply oil to the rockers like Triumph.

The case breather will also be overloaded from the extra displacement. For the I would try to use the later R wheels (1932) which I think are stronger and heavier with a better rod in the D. I don’t know if there is enough room for a roller bearing in the right case. |

.JPG)